Emsland Frischgeflügel &

Celler Land Frischgeflügel

Emsland Frischgeflügel & Celler Land Frischgeflügel

Emsland Frischgeflügel & Celler Land Frischgeflügel

Emsland Frischgeflügel and Celler Land Frischgeflügel are the chicken meat production facilities. The plants are among the most modern chicken meat processing plants in Germany and Europe. The chicken meat is then sold and distributed by Landgeflügel FG Vertriebsgesellschaft.

Emsland Frischgeflügel

essingOur production plant Emsland Frischgeflügel was built in the industrial area at the Eurohafen in Haren and started operations in 2003. In 2007, a second processing and cutting line was added to the plant.

At this location we produce chicken parts from wings to fillets for the food retail industry and industrial processing in any desired weight and packaging unit.

Emsland Frischgeflügel employs around 2,500 people subject to social insurance contributions in full-time shifts.

Celler Land Frischgeflügel

In September 2011, the Celler Land Frischgeflügel production facility in Wietze near Celle was put into operation, further expanding our production capacity. The development of the chicken market and the opportunity to tap into a new large procurement market prompted us to build a production facility in eastern Lower Saxony. It uses the same conceptual configuration as the plant in Haren, which was built back in 2003.

Currently, more than 1,200 people are employed here in 2-shift operation. This makes us the largest employer in the municipality of Wietze.

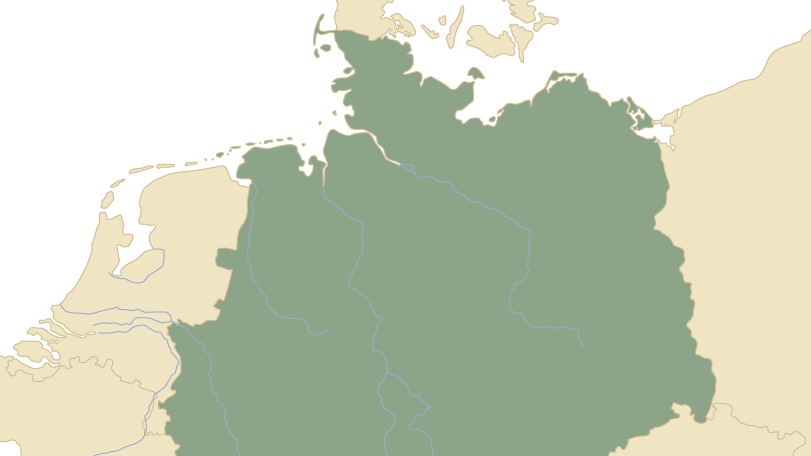

At home in the north

In our two efficient processing and cutting plants, we produce visually, sensorily and microbiologically flawless chicken products for the food retail and processing industry as well as the wholesale trade and the pet food sector.

Emsland Frischgeflügel / Landgeflügel

Emsland Frischgeflügel started operations in 2003 in the industrial area at the Eurohafen shipyard in Haren. In 2007, a second production line was added to the plant

Landgeflügel, based in Haren, distributes the chicken meat products of the Emsland Frischgeflügel slaughterhouse and Celler Land Frischgeflügel.

Celler Land Frischgeflügel

The Celler Land Frischgeflügel slaughterhouse in Wietze was commissioned in September 2011.

Our chicken processing and cutting plants

The best technical equipment and production facilities as well as a minimal consumption of resources guarantee efficient, high-quality food production in our two processing and cutting plants.

1. Our processing plants

At two locations in Lower Saxony, we process and cut up the broilers delivered to us six days a week.

2. Slaughtering

We also ensure responsible handling of animals during slaughter. All employees working with live animals receive special training.

3. Veterinary inspection

The chickens are inspected by veterinarians and inspectors of the district to ensure that they are in perfect condition.

4. Cutting

The cutting of the chicken is largely automated. The resulting cuts are then weighed, portioned and placed in trays.

5. Refinement

In addition to natural products, our assortment also includes variously seasoned and marinated products, for example for barbecue platters, skewers or oven trays.

6. Packaging & shipping

After the products have been packaged, they are picked for the individual customers and then loaded onto our refrigerated trucks.

We can proudly guarantee reliable delivery. Among other things, this is because we operate our own vehicle fleet with around 200 of our own tractor units and trailers.

Emsland Frischgeflügel

Emsland Frischgeflügel

Im Industriepark 1

D-49733 Haren

Telephone: +49 5932 9975 0

Mail: info@landgefluegel.de

Celler Land Frischgeflügel

Celler Land frischgeflügel

Trannberg 1

D-29323 Wietze

Telephone: +49 5146 9844 0

Email: info@landgefluegel.de